engine sealing procedures

Downloads

3E Circuit Excel Engine Sealing

3E Circuit Esxcel Seal Doc

CEMC Engine Sealing Procedure

3rd Category – Touring Cars, Group 3E – Circuit Excel

The Sealing of Rebuilt / Reconditioned Engines

As part of the requirements of racing Group 3E Ciruit Excels, all Engines are require to be sealed at the start of the season or when it is required to be either; Rebuilt / Reconditioned or Replaced with a Wrecker Engine. All engines are to be sealed by a qualified and approved engine sealer.

The requirement of the sealing of a rebuilt / reconditioned engine is to have 3 seals placed by an appointed Engine Sealer using the appropriate sealing sheet.

The following locations are to have the appropriate previsions made prior to the engine sealing process:

TIMING / OIL PUMP COVER

CAMSHAFT SADDLE

CYLINDER HEAD

Rebuilt & Reconditioned Engine Assembly Sealing Process:

1) The engine sealer will check various engine components during engine assembly. Components checked would include, but not limited to: crankshaft, conrods and pistons, bore, stroke, castings, valves, cylinder head and ports, timing components.

2) Ensure engine is ready for assembly, crank assembled with #1 to #3 pistons attached, #4 piston removed and checked prior to assembly to crank.

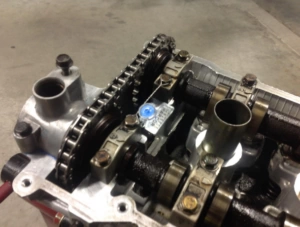

3) Installation of seals to Inner Cam bolts (chain end) to be drilled 2mm as per Cam sealing photo (1 x Seal). Note; The cylinder head shall be fitted with all valves, springs, and retainers, but without camshafts, and the engine sealer will ask for some valves of his choice to be removed for checking.

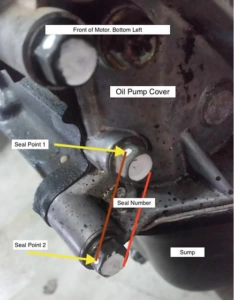

4) Installation of cylinder head (1 x Seal) and timing / oil pump cover (1 x Seal) Note; sealing holes may be drilled under instruction from Motorsport Australia approved sealer at time of engine assembly.

5) Installation of timing / oil pump cover seals is to have two of the pump bolts drilled out to 2mm from the left hand side of the engine.

6) All gaskets and sealing products to be on hand, with 2mm drill bits and hand power drill.

Engine sealing document “Circuit Excel Sealing Sheet” shall be completed and signed by Motorsport Australia approved engine sealer. The numbers of the engine seals applied shall also be recorded in the Vehicle Log Book “Change of Details” page. It is the Competitors responsibility to provide a copy of the sealing sheet to the Category Eligibility officer and to retain their copy and produce if requested by a Motorsport Australia official.

It is recommended by CEMC that each State club setup a Dropbox or Cloud drive where all Engine Sealing documents can be collated. The Engine Sealing form can be filled out on a Desktop or Laptop computer and digitally signed to avoid scanning and transformation into a document.

Engine Seal Locations:

1. TIMING / OIL PUMP COVER SEAL .

2. CAMSHAFT SADDLE SEAL

3. CYLINDER HEAD SEAL

The Sealing of Existing / Second Hand Engines Engine

The requirement of the sealing of an existing / second hand engines is to have 2 seals placed by an appointed Engine Sealer using the appropriate sealing sheet for existing / second hand engines. The seals need to be placed on these locations:

TIMING / OIL PUMP COVER

CAMSHAFT SADDLE

Engine assembly and sealing Process:

The intent of this process is that the engine can be sealed whilst in the car.

1) Installation of seals to Inner Cam bolts (chain end) to be drilled 2mm as per Cam sealing photo (1 x Seal).

2) Installation of timing / oil pump cover seals is to have two of the pump cover bolts drilled out to 2mm from the left hand side of the engine.

A Sealer may instruct owner to drill the bolts out prior to sealing to aid the installation of the seal and the process.

Checks performed at time of engine sealing will consist of.

1) Inspection of throttle body

2) Check of Engine Number, confirmation that engine is of the correct G4FK series.

3) Check/Inspection of head casting markings to ensure that head is of correct engine series and not a later series head with improved port/valve characteristics.

The intent of engine sealing of this type is to ensure engine is sealed such that engine may be checked for eligibility at any stage during competition and the findings of such checks will be proof of compliance / non-compliance to the regulations for all events entered since the engine was sealed. Findings of irregularities at any inspection may result in sanctions that may include, but not limited to disqualification from currently entered event, exclusion from association or state championship or deduction of points received from events previously entered with the same sealed engine.

A “Circuit Excel Sealing Sheet – Existing / Second Hand Engines” shall be used to record the findings of the inspection and unique numbers of the engine seals applied by the engine sealer. The numbers of the engine seals applied shall also be recorded in the Vehicle Log Book “Change of Details” page. It is the Competitors responsibility to provide a copy of the sealing sheet to the Category Eligibility officer and to retain their copy and produce if requested by a Motorsport Australia official.

It is recommended by CEMC that each State club setup a Dropbox or Cloud drive where all Engine Sealing documents can be collated. The Engine Sealing form can be filled out on a Desktop or Laptop computer and digitally signed to avoid scanning and transformation into a document.